-

Cavitation Resistant

-

Requires No Heat

-

Excellent Adhesion

-

100% Solids

-

Exceptional Flexibility

-

Use for...

-

Coating

-

Resurfacing

-

Protecting

-

Creating and Repairing Flexible Seals, Gaskets & Seats

RESURFACING, COATING AND PROTECTING. SUPERIOR STRENGTH, DURABILITY AND ADHESION WITH FLEXIBILITY, ABRASION RESISTANCE, AND ELONGATION.

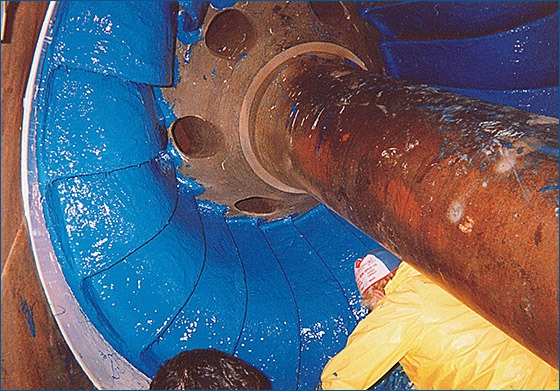

FLEXICLAD DuraTough DL is a two component, 100% solids, fluid consistency elasto-ceramic polymer composite specifically formulated to surface and protect equipment subject to cavitation accelerated erosion/corrosion.

DuraTough combines the superior strength, durability and adhesion of an epoxy with the exceptional flexibility, abrasion resistance and shock absorbency of an elastomeric urethane.

Flexiclad DuraTough DL is ideal for coating, resurfacing & protecting equipment prone to cavitation attack as well as creating and repairing flexible seals, gaskets, seats, etc., on machinery and equipment such as heat exchangers, pumps, valves & piping systems.

| Volume capacity / 0.5 kg : 27 in3 / 442 cc |

|---|

| Mixed density : 0.041 lbs / in3 (1.13 gm / cc) |

| Coverage rate / 0.5 kg : 0.5 m2 @ 0.75 – 0.9 mm |

| Shelf life :Two years |

| Volume Solids : 100% |

| Mixing ratio Base / Activator / Aggregate (volume): 5.7 / 1 |

| Mixing ratio Base / Activator (weight): 6.5 /1 |

| Working Life 25ºC : 30 min |

| Initial Set 25ºC : 1 h |

| Maximum Overcoating 25ºC : 6 h |

| Full Cure : 72 h |

| Hardness – Shore D |

|---|

| (ASTM D-1002) : 1050 psi (74 kg/cm2) |

| (ASTM D-1002) : 1100psi (77 kg/cm2) |

| (ASTM D-1002) : 1200psi (84 kg/cm2) |

| (ASTM D-1002) : 1200psi (84 kg/cm2) |

| (ASTM D-2240) : 55 |

| (ASTM D1876) > 30 (pli) pound / inch (> 5.3 kN/m) |

| (ASTM G32) Frequently: 20 KHZ; amplitude: 0.001 inches (0.0254mm) : 240 micron (0.24 mm) CMDL* |

| (ASTM G32) Frequently: 20 KHZ; amplitude: 0.001 inches (0.0254mm) : 50 micron (0.05 mm) CMDL* |

| (ASTM G32) Frequently: 20 KHZ; amplitude: 0.001 inches (0.0254mm) : 60 micron (0.06 mm) CMDL* |

| * CMDE: Cumulative Mean Depth of Loss |

| Acetic ccid 0-10% —– NR |

|---|

| Ammonium hydroxide (amoniac) (0-10%) —– G |

| Ethanol —– NR |

| EX – Suitable for most applications including immersion |

| G – Suitable for intermittent contact splashes etc |

| Hexane —– G |

| Methanol —– NR |

| Mineral Oil —– G |

| NR – Not Recommended”””” |

| Oxalic acid —– G |

| Phosphoric acid (0-10%) —– G |

Technical data

Physical properties

Chemical resistance