CeramAlloy CL+AC – ceramic polymer, fluid flow erosion, corrosion resistance

- Country Origin: USA

- Working Life: 40′ – 240′ depend on the environment temperature

- Shelf life: Unlimited

-

Z

Apply by Brush, Roller or Flexible Applicator

-

Z

Requires No Heat

-

Z

Unlimited Shelf Life

-

Z

100% solids

-

Z

Safe & Simple To Use

-

Repair...

-

Z

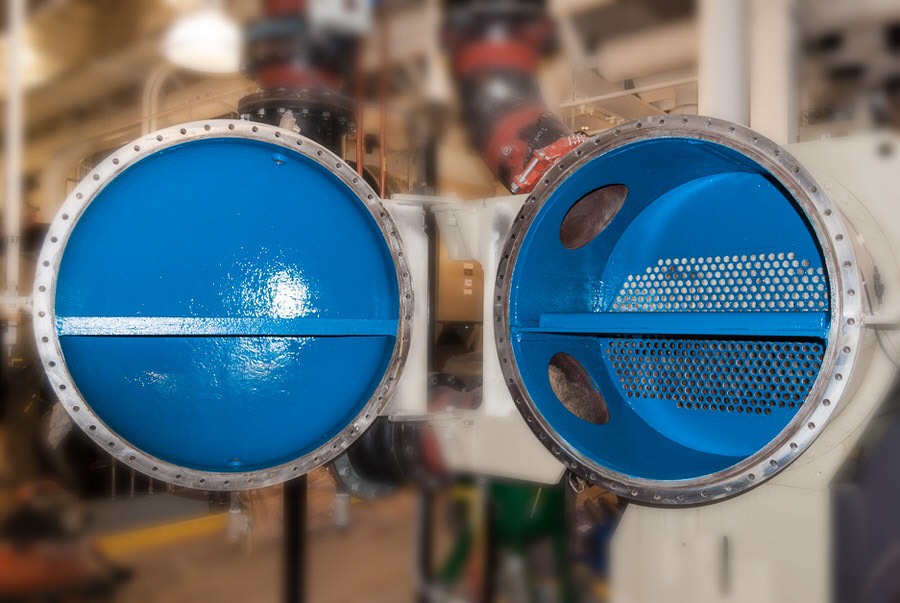

Pumps

-

Z

Cooling Towers

-

Z

Heat Exchanger Tube Sheets & Water Boxes

-

Z

Valves & Pipework, Housings & Tanks,...

The advantage of high performance polymer composites technologies used for repairing, resurfacing, industrial maintenance and fluid flow problems are saving you time, money cause quickly cures, easy to check the surface & temperature monitoring in plate instead waiting for full cure as the traditional.

OUTSTANDING EROSION/CORROSION RESISTANCE!

REPAIRS DAMAGED EQUIPMENT - PROTECTS NEW COMPONENTS.The Most Advanced Polymer Composite Coating System Available!

METALCLAD CeramAlloy CL+AC is a 100% solids, two component, liquid polymer composite used for repairing, resurfacing and coating components to provide outstanding fluid flow erosion and corrosion resistance.

When mixed, METALCLAD CeramAlloy CL+AC is a viscous liquid. CL+AC cures to a hard, ceramic-like material with an extremely smooth surface finish.

High Performance Polymer Composite for resurfacing and protecting all types of fluid flow components from aggressive erosion and corrosion damage.

| Volume capacity per kg / Thể tích / kg : 36 in3 / 592 cc |

|---|

| Mixed density / Khối lượng riêng (tỉ trọng) sau khi trộn : 0.061 lbs / in3 (1.69 gm / cc) |

| Coverage rate per kg. @ 12 – 15 mils / Diện tích phủ 1kg : 1.4 m2 độ dày 0.3 – 0.35 mm |

| Shelf life / Thời gian lưu kho : Indefinite / vô thời hạn |

| Volume Solids / Thể tích đóng rắn : 100% |

| Mixing ratio / Tỷ lệ trộn Base / Activator (volume / theo thể tích) 3.3 / 1 |

| Mixing ratio / Tỷ lệ trộn Base / Activator (weight / theo trọng lượng) : 6 /1 |

| Working Life / Thời gian thi công ở 25ºC : 60 phút |

| Cure Times / Thời gian đóng rắn ở 25ºC : 12 giờ |

| Full cure / Thời gian đóng rắn hoàn toàn ở 25ºC : 24giờ |

| Chemical Immersion / Ngâm trong hóa chất : 72 giờ |

| Compressive strength / Chịu lực (độ bền) nén |

|---|

| (ASTM D-115): 652 V / Mil |

| (ASTM D-149, method A / phương pháp A): 6.1 Kv |

| (ASTM D-150) : 7.5 |

| ASTM D-1002 : 2,500 psi (175 kg/cm2) |

| ASTM D-1002 : 2,800 psi (196 kg/cm2) |

| ASTM D-1002 : 4,000 psi (280 kg/cm2) |

| ASTM D-1002 : 4,100 psi (287 kg/cm2) |

| ASTM D-2240: 85 |

| ASTM D-257 : 1 x 1015 ohm/cm |

| ASTM D-257 : 1 x 1015 ohms |

| Acetic acid0-10%: —– EX | Methanol —– G |

|---|---|

| Aceton —– G | Mineral Oil / Dầu khoáng —– EX |

| Aviation fuel (nhiên liệu máy bay) —– EX | Nitric acid / Axit Nitric (0-10%) —– EX |

| Butyl alcohol (N-butanal) —– EX | Nitric acid / Axit Nitric (10-20%) —– G |

| Calcium chloride / Canxi clorua —– EX | Phosphoric acid / Axit Phosphoric (0-10%) —– G |

| Crude oil / Dầu mỏ. —– EX | Potassium chloride / Potassium Chloride (Kali Clorua) —– EX |

| Diesel fuel / Dầu diezel —– EX | Propyl alcohol / Dung môi IPA (Rượu isopropanol) —– EX |

| Ethyl alcohol / Ethanol —– G | Sodium chloride / Natri Clorua —– EX |

| Gasoline / Xăng —– EX | Sodium hydroxide / Natri Hidroxit —– EX |

| Heptan (Heptane, Dipropyl Methan) —– EX | Sulfuric acid / Axit Sulfuric (0-10%) —– EX |

| Hydrochloric acid / Axit Clohydric (0-10%) —– EX | Sulfuric acid / Axit Sulfuric (10-20%) —– G |

| Hydrochloric acid / Axit Clohydric (10-20%) —– G | Toluen (Metylbenzen) —– EX |

| Kerosene / Dầu hỏa —– EX | Xylene —– EX |

| EX – Suitable for most applications including immersion | |

| G – Suitable for intermittent contact splashes etc | |

| NR – Not Recommended”””” |

Technical data

| Volume capacity per kg / Thể tích / kg : 36 in3 / 592 cc |

|---|

| Mixed density / Khối lượng riêng (tỉ trọng) sau khi trộn : 0.061 lbs / in3 (1.69 gm / cc) |

| Coverage rate per kg. @ 12 - 15 mils / Diện tích phủ 1kg : 1.4 m2 độ dày 0.3 - 0.35 mm |

| Shelf life / Thời gian lưu kho : Indefinite / vô thời hạn |

| Volume Solids / Thể tích đóng rắn : 100% |

| Mixing ratio / Tỷ lệ trộn Base / Activator (volume / theo thể tích) 3.3 / 1 |

| Mixing ratio / Tỷ lệ trộn Base / Activator (weight / theo trọng lượng) : 6 /1 |

| Working Life / Thời gian thi công ở 25ºC : 60 phút |

| Cure Times / Thời gian đóng rắn ở 25ºC : 12 giờ |

| Full cure / Thời gian đóng rắn hoàn toàn ở 25ºC : 24giờ |

| Chemical Immersion / Ngâm trong hóa chất : 72 giờ |

Physical properties

| Compressive strength / Chịu lực (độ bền) nén |

|---|

| ASTM D-695 : 13,500 psi (945 kg/m2) |

| Flexural strength / Chịu lực (độ bền) uốn |

| ASTM D-790 : 8,000 psi (560 kg/cm2) |

| Hardness - Shore D / Độ cứng shore D |

| ASTM D-2240: 85 |

| Taber Abrasion Resistance dry / Độ chịu mài khô |

| ASTM D-4060, CS-17 Wheel, 1000 cycles, 1 Kg Load Dry - 12.5 mm3 loss |

| Taber Abrasion Resistance wet / Độ chịu mài ướt |

| ASTM D-4060, H-10 Wheel, 1000 cycles, 1 Kg Load Wet - 160.6 mm3 loss |

| Tensile Shear Adhesion steel / Độ bền cắt bám dính trên thép |

| ASTM D-1002 : 4,000 psi (280 kg/cm2) |

| Tensile Shear Adhesion steel / Độ bền cắt bám dính trên thép |

| ASTM D-1002 : 2,800 psi (196 kg/cm2) |

| Tensile Shear Adhesion copper / Độ bền cắt bám dính trên đồng |

| ASTM D-1002 : 2,500 psi (175 kg/cm2) |

| Tensile Shear Adhesion stainless steel / Độ bền cắt bám dính trên thép không rỉ |

| ASTM D-1002 : 4,100 psi (287 kg/cm2) |

| Surface resistivity / Suất điện trở mặt |

| ASTM D-257 : 1 x 1015 ohms |

| Volume resistivity / Suất điện trở khối |

| ASTM D-257 : 1 x 1015 ohm/cm |

| Dielectric constant / Hằng số điện môi |

| (ASTM D-150) : 7.5 |

| Dielectric strength / Độ bền điện môi |

| (ASTM D-115): 652 V / Mil |

| Breakdown Voltage / Điện áp đánh thủng |

| (ASTM D-149, method A / phương pháp A): 6.1 Kv |

Chemical resistance

| Acetic acid0-10%: ----- EX | Methanol ----- G |

|---|---|

| Aceton ----- G | Mineral Oil / Dầu khoáng ----- EX |

| Aviation fuel (nhiên liệu máy bay) ----- EX | Nitric acid / Axit Nitric (0-10%) ----- EX |

| Butyl alcohol (N-butanal) ----- EX | Nitric acid / Axit Nitric (10-20%) ----- G |

| Calcium chloride / Canxi clorua ----- EX | Phosphoric acid / Axit Phosphoric (0-10%) ----- G |

| Crude oil / Dầu mỏ. ----- EX | Potassium chloride / Potassium Chloride (Kali Clorua) ----- EX |

| Diesel fuel / Dầu diezel ----- EX | Propyl alcohol / Dung môi IPA (Rượu isopropanol) ----- EX |

| Ethyl alcohol / Ethanol ----- G | Sodium chloride / Natri Clorua ----- EX |

| Gasoline / Xăng ----- EX | Sodium hydroxide / Natri Hidroxit ----- EX |

| Heptan (Heptane, Dipropyl Methan) ----- EX | Sulfuric acid / Axit Sulfuric (0-10%) ----- EX |

| Hydrochloric acid / Axit Clohydric (0-10%) ----- EX | Sulfuric acid / Axit Sulfuric (10-20%) ----- G |

| Hydrochloric acid / Axit Clohydric (10-20%) ----- G | Toluen (Metylbenzen) ----- EX |

| Kerosene / Dầu hỏa ----- EX | Xylene ----- EX |

| EX – Suitable for most applications including immersion | |

| G – Suitable for intermittent contact splashes etc | |

| NR – Not Recommended"""" |

Related products

-

CeramAlloy HTL – outstanding erosion/corrosion resistance at elevated temperatures

-

CeramAlloy HTP – outstanding erosion/corrosion resistance at elevated temperatures

-

CeramAlloy CP+AC – erosion, corrosion repair, resurfacing

-

DurAlloy – repairs, rebuild metal surface

-

CeramAlloy EBX – abrasion resistance & extend the service life

-

DuraWrap – carbon fiber repair, reclaim, reinforce & extend the life of all type pipes, tanks

-

CeramAlloy CP+ outstanding erosion/corrosion resistance nuclear environment

-

CeramAlloy CBX – abrasion resistance & extend the service life